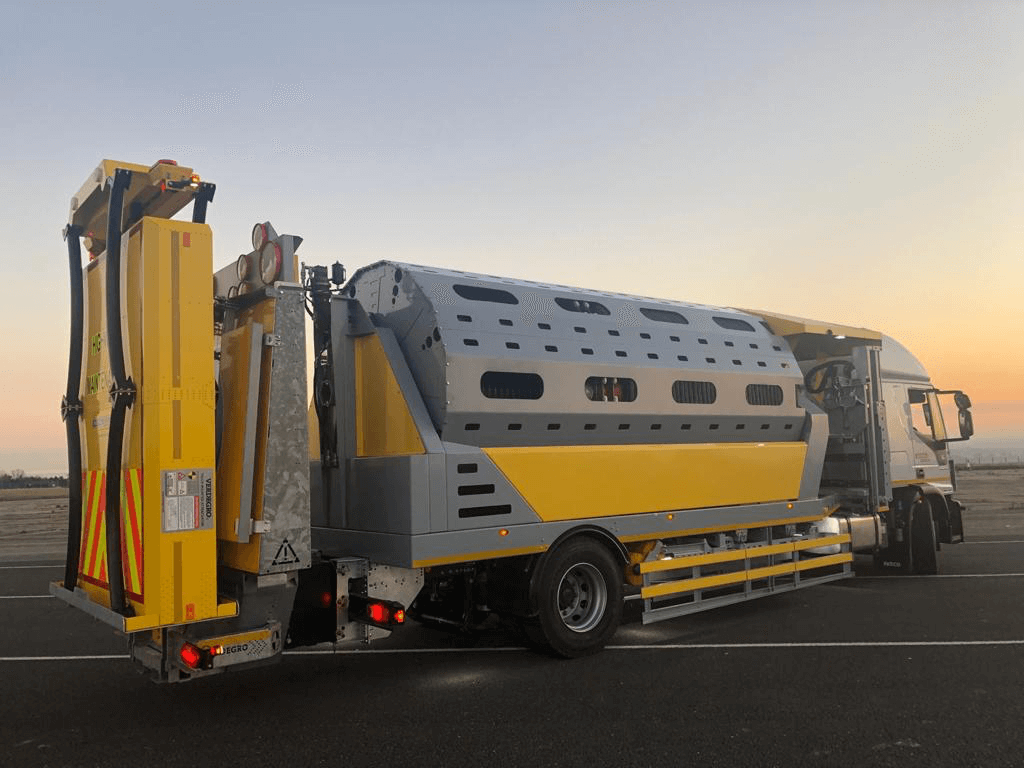

The Verdegro Autocone 2.0

The Verdegro Truck Mounted patented Autocone 2.0 system, the fully automatic cone deployment system can be optional equipped with a patented rumble mat layer, and optional TMA mounted on the Truck. The Autocone system can be installed on any standard 18T chassis with air suspension.

Watch a video here

OPTIONAL

- The Autocone 2.0 system can be installed on a standard 18-ton truck chassis of any major brand, equipped with air suspension

TECHNICAL SPECIFICATIONS (SYSTEM AND GENERAL)

Cone Type & Capacity

- Standard one-piece traffic cones, 1000 mm height, 560 × 560 mm base. Cones not included!

- Weight approx. 7.6 kg / 16 lbs per cone

- Black base with white and red high-reflective striping film, according to applicable specifications

- Extra-thick and extra-heavy square base design

- Reinforced edges and reinforced corner rings, suitable for hydraulic clamp handling

- System can be adapted for locally used cones on request, if technically feasible

Autocone Power Supply

- Powered by truck chassis engine PTO

- Hydraulic pump for all cone handling and operating functions

Autocone Finish & Colour

- The standard colour is Yellow (RAL 1023). Other RAL colours available on request

Patented Design

- This design is protected by patents in the Netherlands (NL2021455), Europe (EP3608475), and the United States (US11,105,504)

TECHNICAL SPECIFICATIONS (STRUCTURAL COMPONENTS)

Autocone Sub-Frame

- High-resistance steel profiles and plates, welded construction

- Bolted to vehicle chassis with bolts and bars

- Supports cone storage, cone picking & placing units and guiding rails

Autocone Guiding Rails

- One set per side (left / right)

- High-resistance steel profiles and plates

- Mounted between axles, hydraulically extendable and retractable

- Specially designed and tested by Verdegro for reliable operation

TECHNICAL SPECIFICATIONS (HANDLING & OPERATION)

Autocone Storage Unit

- Barrel-type design, made of high-resistance steel profiles and aluminium plates

- Hydraulic motor driven spiral feeding system for horizontal cone rotation

- 8 columns, 50 cones per column, total capacity 400 cones

- Fully enclosed design to protect cones and moving components from dirt and weather

Autocone Picking & Placing Chamber

- Mounted in front of cone storage, semi-closed structure with rain cover

- Fully hydraulic operation: pull out, push back and transfer cones left or right

- Electronic and optical sensors for cone position detection

Autocone Catching Clamps

- One set per side (left / right), mounted on lifting units

- Steel hinge plate construction

- Hydraulically operated cylinders for fast gripping and releasing of cones

Mobitrack

Mobitrack can be integrated into your products, providing accurate and real-time location data. It keeps a detailed record of past locations, allowing you to see where your products have been. Mobitrack is simple to integrate into both new and existing products.

Statistics show that many accidents still occur involving road users and workers. To enhance the safety of both drivers and workers, Mobitrack can be configured to work with safety alert systems. This integration allows it to send alerts to drivers, warning them of nearby workers and significantly increasing safety.

Mobitrack is automatically integrated with a wide range of safety alert systems, including Google, Waze, Flitsmeister, Monotch, and your country’s traffic control system. We are the only manufacturer with such extensive integration across various safety alert platforms.

Additionally, the advanced implementation of the Mobitrack module allows you to request detailed information about your products, ensuring you have all the necessary data at your disposal.

Mobitrack – Basic

- Track your products’ locations accurately in real-time.

- Keeps a location history of where your products have been.

- Easily integrates with any product.

- Display your product in Mobilityplanner for easy access.

- Integration with safety alert systems to improve safety and send warnings.

Request additional information from your products: arrow left/right, cushion down/up, lights on/off etc.

Mobitrack – Advanced

- Track your products’ locations accurately in real-time.

- Keeps a location history of where your products have been.

- Easily integrates with any product.

- Display your product in Mobilityplanner for easy access.

- Integration with safety alert systems to improve safety and send warnings.

- Request additional information from your products: arrow left/right, cushion down/up, lights on/off etc.

Contact us

"*" indicates required fields